atmos:535:projects:hewlett_packard_5890_series_ii_gc-ms

Table of Contents

Gas Chromatograph/Mass Spectrometer

Theory

- Six Basic Principles in Performing Gas Chromatography:

- Flow Controller

- Sample Introduction Device

- Column

- Oven

- Detectors

- Computer Interface (Data Management)

Gas Chromatography

- Process involves the physical separation of compounds in a mixture by injecting the mixture into a tube (column) that contains a silica based inert compound. The mixture is called the mobile phase and the silica compound is known as the stationary phase. A carrier gas is used to flush the mobile phase through the column. The stationary phase will pass some compounds and slow down others.

- Compounds in mixture are identified by their retention times.

- Retention time is the time it takes for the individual compound to pass through the entire column.

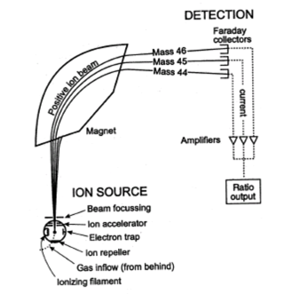

Mass Spectrometry

- Mass spectrometry deals with shattering compounds into component ions by passing sample through an ionization (high voltage) source.

- The ions are separated by a large magnetic or electric field. The ions are then collected in “traps” and then analyzed. A charge to mass ratio is calculated and a mass spectra is generated.

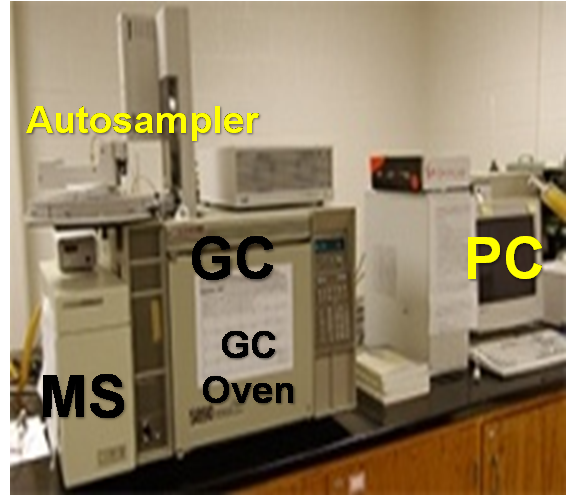

Interface and Equipment

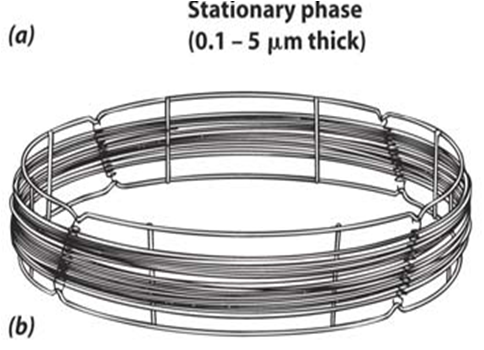

GC Column

- Capillary tube of length between 1 to 100 m and thickness range of 0.25 to 5 mm

- Column is either packed with silicone based stationary phase or inside is coated with the material.

Hardware

- Nitrogen Gas Cylinder

- Carrier gas for mobile phase, non-reactive and inert to sample being tested

- Hydrogen Gas Cylinder

- Used to combust sample at the end of the analysis

- Plumb Lines

- To connect cylinders to GC/MS

- Vacuum Pump

- Used for MS which operates under low pressure conditions

Computer Interface

- The GC/MS can either be run automatically or manually.

- Both require use of computer program.

- PC and software are Windows based.

- Software contains program that controls oven temperature such that the oven starts at a low temperature and ramps up to a higher temperature at different heating rates.

Calibration

- Calibration standard is made of a pure compound (e.g. bromofluorobenzene) and is used for quality control of the GC/MS.

- The compound has a specific retention time and a specific mass spectra.

- Quality control is usually done at after a fixed number, usually 20, of samples have been analyzed.

- Quality assurance is done whenever the instrument cannot be calibrated.

- QA steps include:

- Changing the check standard - an aged check standard can affect accuracy of instrument

- Conditioning the column - bake the column to a temperature of 300oC to remove contaminants

- Replacing the column - cracks and fissures

- Checking the carrier gas flow rate - mobile phase may be going faster or slower than normal

- Replacing the entire instrument - GC oven may be irreparable, internal plumbing damaged, etc

Purpose and Performance

- A combined GC/MS has the ability to detect minute quantities of a solute contained within a larger volume of solvent. For example, a properly calibrated GC/MS can quantify organic contaminants, such as volatile organic carbons (VOC) on the order of parts per billion present within large volumes of soil, water or air.

- This is useful in environmental sampling especially when looking for compounds that adversely affect human health.

- Liquid or air samples on the order of milliliters can be sampled.

- If using the direct inject method, microliters of sample are usually used.

- Sample Injection

- Non-Direct Inject

- Usually done with help of autosampler.

- Nitrogen gas is bubbled into a tube containing sample to draw out the volatile parts of the mixture.

- Semi or non-volatile compounds are not usually sampled by GC.

- Mixture is held in a trap until GC signals the computer to start the oven program.

- Mixture is injected into the inlet of both the GC and MS at the same time. Both instruments collect data at the same time.

- As the compound is sent through and out of the column, the MS shatters each compound into ions as they are ejected and quantifies their mass spectra.

- At the end of the column, there is a flame ionizing detector, FID, which combusts the sample with the aid of hydrogen gas.

- The GC quantifies the amount of burn and the time of ionization to render a retention time and concentration.

- Direct Inject

- Analyst will start computer program and inject sample at same time rather than using autosampler.

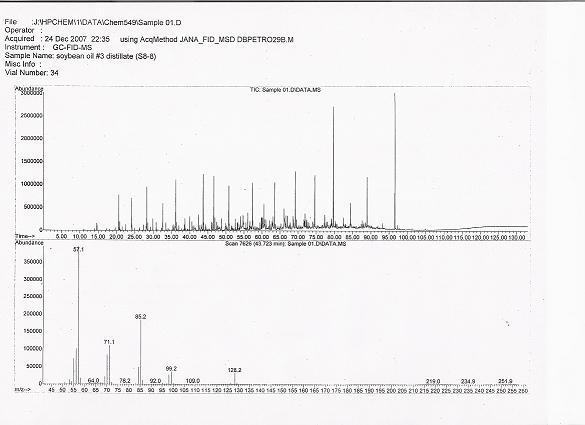

Data

- Top picture shows the chromatogram.

- Chromatogram shows peaks for each compound in the mixture according to retention time. It also shows concentrations of the compounds.

- Integrated area of peak is the concentration.

- Bottom picture shows the mass spectra.

- Using the reference spectra library that comes with the GC/MS software, an analyst can identify each peak by clicking on the highest point of the peak.

- At the end of the mass spectra is the molecular weight of the ion.

- For example, chloroform is a chlorinated VOC with molecular weight of 119.5 g/mol. The ion molecular weight will be somewhere between 116 and 118 g/mol. The discrepancy is due to isotopes of carbon and chlorine.

Usage and Deployment

- Liquid samples are collected in bottles and air samples are collected in bags.

- Air samples can be direct injected into GC/MS from the bag instead of by autosampler or syringe as with liquid samples.

- Does not perform real time sampling.

- In a production laboratory setting, a GC/MS can be dedicated to performing emergency sampling which requires a fast turn around.

- Most samples that are being tested for VOCs have an average sampling time of 30 minutes from injection to the end of the analysis.

- GC/MS is designed to be used in a stationary environment.

- Complex setup of GC, MS, computer interface, carrier gas cylinders, and plumbing make it difficult to use in a mobile setting (e.g. aircraft).

- Less sophisticated instruments can be used in mobile platforms.

- Martian land rover has onboard GC/MS but uses much less sophisticated sampling techniques due to space constraints.

- Fields Other Than Environmental and Space Science GC/MS Is Used for

- Forensic Science

- Toxicology

- Drug Screening

- Pesticides

- Power Consumption

- GC/MS can be used on standard 120 V (220 V if 50 Hz cycling alternating current) power line but requires high current for MS.

- 800 W power consumption

- Cost

- $40,000 for GC/MS combination

- $1000 for PC and software

- $500 for gas cylinder - lasts approximately three weeks with 24 hour consumption

Acknowledgments and References

- University of North Dakota, Chemistry Department, Abbott Hall GC/MS Lab

- HP 5890 GC/Agilent 5973 MS User Manual

- TestAmerica Labs, Inc (Formerly Severn Trent Labs), Edison, New Jersey

atmos/535/projects/hewlett_packard_5890_series_ii_gc-ms.txt · Last modified: 2020/01/29 17:25 by 127.0.0.1